Search This Supplers Products:Galvanized PipeGalvanized TubeShed PipeWelded PipeSeamless pipeSprial pipe

- Home

- About us

- Products

- Greenhouse Kits / Frame Galvanized Steel Pipe Tube

- Galvanized Steel Round Pipe / Tube

- Galvanized Steel Square Pipe / Tube

- Galvanized Steel Rectangular Pipe / Tube

- Galvanized Steel Oval Pipe / Tube

- ERW Welded Round Pipe / Tube

- ERW Welded Square Pipe / Tube

- ERW Welded Rectangular Pipe / Tube

- Seamless Steel Pipe / Tube

- Spiral Steel Tube Threaded Steel Pipe

- Tunnel Greenhouse Frame Kits Galvanized Steel Tube

- Faqs

- News

- Certificate

- Contact us

Welded Spiral Steel Tube Threaded Steel Pipe

- group name

- Spiral Steel Tube Threaded Steel Pipe

- Min Order

- 1 ton

- brand name

- HYHY STEEL

- Nearest port for product export

- Tianjin, China

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T, L/C

- update time

- Tue, 06 Jun 2017 16:38:15 GMT

Paramtents

Outer Diameter 219-2820mm

Thickness 5-20mm

Length 6-12M

Usage construction&transportation

Brand Name HUAYU HONGYE

Grade Q195/Q235 / API 5L

Surface Oiled or black painted to prevent rust.

Application Crude oil pipelines, Natural gas pipelines, Water Supplylines, Foundation piles, Industrial pipeline networks, Steel construction, etc.

Packing terms In bundles

Packging & Delivery

-

Min Order1 ton

Briefing

Spiral Steel Tube Threaded Steel Pipe

Detailed

Spiral Weld Pipe, as the name implies, is a steel pipe which has a seam running its entire length in a spiral form. In the past, due to the method of manufacture, Spiral Welded pipe was relegated to low pressure and structural applications. With the development of the Submerged Arc Welding process, the production of large hot rolled coils of sufficient width and the development of dependable non-destructive testing methods, it is now possible to produce Spiral Weld pipe for high pressure service.

Because of the method of manufacture, a wide variety of diameters can be produced. The diameter tolerance is small, particularly with regard to ovality; and the pipe, due to its axial symmetry, has an inherent straightness. The length range is infinite and is controlled only by the economics of transportation. Spiral Weld Pipe is used for dredging, slurry, water and other pipelines, as well as piling and structural applications. Spiral Weld Pipe is produced in accordance with the dimensional and tolerance requirements of various ASTM, AWWA, and API Specifications.

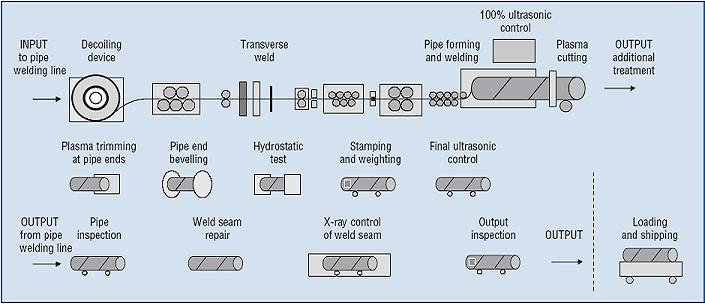

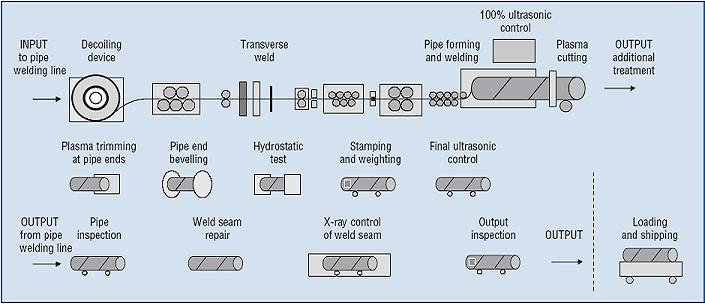

Present Spiral Weld mills consist of a de-coiling device (in the case of strip base material) or a plate preparation table (where the base material is in plate form) a strip connecting welder, straightening rollers, edge preparation tools (shearing and trimming), prebending devices, a three roller bending and cage forming system, an internal welder, an external welder (both Submerged Arc), ultrasonic testing apparatus and cutting devices. The material passes through all these production stages continuously. The angle between the flat strip being I fed into the machine and the finished pipe leaving the machine controls the pipe diameter in ratio to strip width and the angle of the weld in the pipe.

Because of the method of manufacture, a wide variety of diameters can be produced. The diameter tolerance is small, particularly with regard to ovality; and the pipe, due to its axial symmetry, has an inherent straightness. The length range is infinite and is controlled only by the economics of transportation. Spiral Weld Pipe is used for dredging, slurry, water and other pipelines, as well as piling and structural applications. Spiral Weld Pipe is produced in accordance with the dimensional and tolerance requirements of various ASTM, AWWA, and API Specifications.

Please contact me if you have any question!

Best regards!

Allison